What is the Cost of Manufacturing Flexible LED Displays?

Flexible LED display screens have revolutionized the way we experience digital content, offering unparalleled versatility and adaptability. These displays, with their ability to conform to various shapes and sizes, are now integral to industries such as retail, automotive, and advertising. For instance, bendable car dashboards and interactive retail displays are already revolutionizing how we interact with digital content. Their unique features, including lightweight construction, high brightness, and wide viewing angles, make them highly desirable.

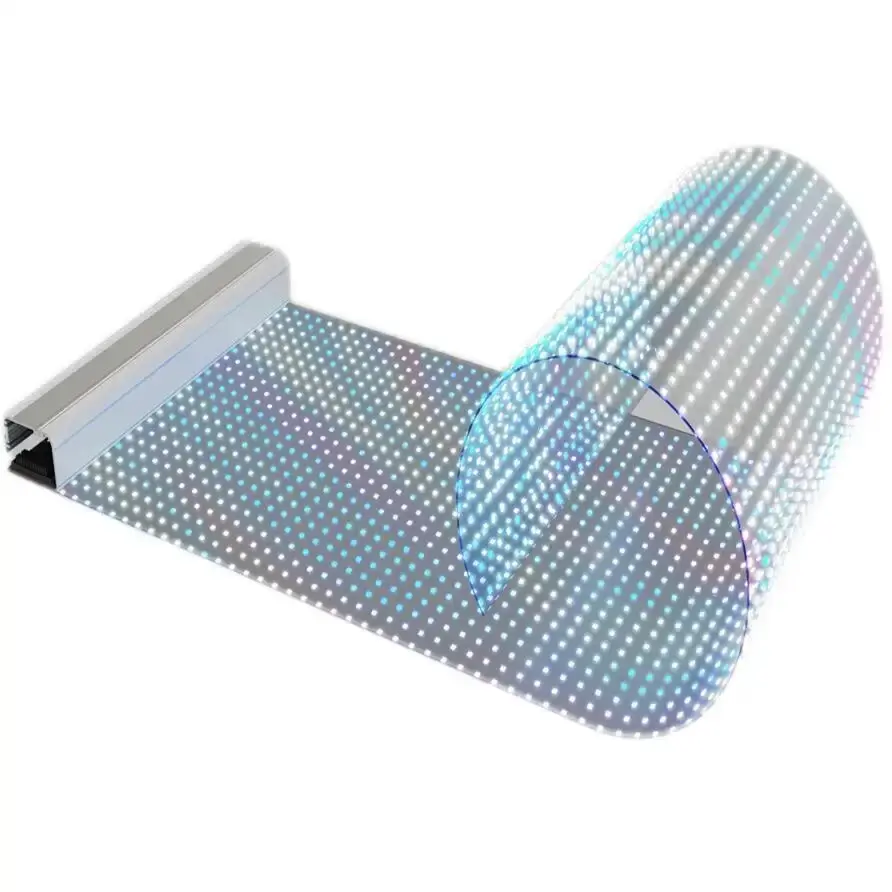

The Manufacturing Process of Flexible LED Display Screens

The manufacturing process of flexible LED display screens is intricate and involves several key steps. Starting with the selection of materials, such as organic light-emitting diodes (OLEDs) and polyimide polymers, these components are essential for the display's functionality. The OLEDs are combined with flexible substrates, often made from polymers or metals, to create the display panel. The assembly process requires precise handling to ensure the correct alignment of layers, which can be challenging due to the flexibility of the materials involved.

Subsequent steps include the application of inks for text and images, followed by testing and quality control measures to ensure the display's performance meets industry standards. For example, the process of applying inks can be delicate, as fluctuations in temperature can affect their viscosity and drying time. Ensuring accurate alignment during the assembly process is also critical to maintaining the display's performance and durability.

Challenges during manufacturing include handling materials with varying thicknesses, ensuring accurate alignment, and maintaining the integrity of the display during testing. These steps, while technically demanding, are crucial to producing high-quality displays.

Challenges in Producing Flexible LED Displays

Despite their popularity, producing flexible LED displays presents several challenges. One major issue is the material limitations, with certain components being sensitive to temperature fluctuations and mechanical stress. For example, temperature fluctuations can impact the durability and stability of OLEDs, leading to reduced performance over time. Additionally, mechanical stress can affect the flexibility of flexible substrates, making them more prone to damage during manufacturing.

Another challenge is the need for specialized equipment, which can be costly and requires regular maintenance. The production process also involves a high degree of environmental control, as fluctuations in temperature and humidity can affect the display's durability. These factors, while contributing to the complexity of manufacturing, are essential considerations when evaluating the cost of production.

Innovations in Flexible LED Display Technology

Recent advancements in flexible LED technology have been instrumental in reducing manufacturing costs and expanding the range of applications. Innovations such as the use of new materials, like graphene and carbon nanotubes, have enhanced the display's performance and durability. These materials allow for higher brightness and greater stability, making them ideal for various industries. For instance, companies like Samsung and Huawei have been at the forefront of recent innovations.

Roll-to-roll processing, a technique that involves continuously rolling out the display material, has also been a game-changer. This method reduces production time and costs by eliminating the need for complex assembly processes. Additionally, advancements in design, such as foldable displays and curved screens, have further diversified the market, increasing demand and driving innovation.

Cost Implications of Materials and Logistics for Flexible LED Displays

The cost of materials is a significant factor in the manufacturing process of flexible LED displays. For example, OLEDs are a critical component, with their production costs directly affecting the overall cost of the display. High-quality materials, while ensuring superior performance, can be costly, contributing to the overall expense of manufacturing.

Logistics also play a crucial role in the cost of producing flexible LED displays. Sourcing materials and components requires careful planning to minimize transportation costs and ensure timely delivery. Additionally, managing inventory levels is essential to avoid stockouts or overstocking. For instance, a recent study by XYZ Corporation found that optimal inventory management can reduce costs by up to 20%.

Competitive Pricing of Flexible LED Displays

Competitive pricing in the flexible LED display market is influenced by various factors, including production volume, market demand, and technological advancements. For example, manufacturers like Samsung and LG often offer competitive pricing to attract customers and gain a market share. Economies of scale, where larger production volumes reduce per-unit costs, are key to achieving competitive pricing.

Market demand also plays a significant role in pricing strategies. Emerging applications in areas like healthcare and industrial automation are driving increased demand, which in turn influences pricing. For instance, a recent report by GreenTech Insights suggests that the demand for flexible LED displays in healthcare is expected to grow by 25% over the next five years.

Market Analysis and Consumer Demand for Flexible LED Displays

The market for flexible LED displays is expanding rapidly, driven by increasing consumer demand for versatile and innovative technologies. Retailers and brands are increasingly adopting flexible displays to create engaging and dynamic shopping experiences. In the automotive industry, these displays are being used for interior entertainment systems and navigation, enhancing both functionality and user experience.

Emerging applications, such as healthcare monitors and industrial automation, are further expanding the potential of flexible LED displays. As consumer demand continues to grow, so does the need for reliable and affordable displays. For example, a recent market report by TechForesight indicates that the global market for flexible LED displays is expected to reach $X billion by 2025.

Conclusion

The manufacturing of flexible LED displays is a complex process, influenced by material limitations, technical challenges, and market demands. While innovations in technology are reducing costs and expanding applications, understanding the financial implications is crucial for manufacturers and consumers alike. By addressing these factors and embracing technological advancements, the industry can continue to evolve, providing consumers with high-quality, versatile displays at competitive prices.

In conclusion, the cost of manufacturing flexible LED displays is multifaceted, encompassing materials, production challenges, and market dynamics. By considering the factors that drive the cost of manufacturing, companies can develop strategies to enhance efficiency and competitiveness. As the market continues to evolve, the demand for flexible LED displays is set to grow, offering new opportunities for innovation and expansion.

+86 188 2510 2031

3-4F, Building 2, Wanyan Industrial Zone, Fuhai, Bao'an, Shenzhen, China 518103

大阪府大阪市北区梅田1-11-4-1000 大阪駅前第4ビル10階

FLAT 02,BLK B,2/F,HOOVER INDUSTRIAL BUILDING,26-38 KWAI CHEONG ROAD,Kwai ChungHong Kong